I like the shotgun that comes with the ThreeA Grunt, but I wanted to make something a bit more compact, something for close contact, maneuvering in tight spaces, ‘breaching’ etc. I went for the ubiquitous side-by-side doubled barrelled shotgun.

For equipment I’ve made for figures before, they tend not to be completely scratch built and I tend to use bits from my 1/6 kitbash ‘bits box’ where possible. For this shotgun I would need a trigger with guard as they are a pain to make as I’ve learned before. I know it is a double barrelled shotgun, but a single trigger will suite just fine for firing both barrels.

The main tools I used are shown below.

The little saw is the best thing I ever bought for this kind of work. Nail files are really useful, they give you a flat surface to work on. I also use various grades of sand paper and emery paper. The glue, as shown, is a thin super glue that can be obtained from Games Workshop vendors. The great thing about it is, it comes with a little brush inside which gives you loads of control. Over balsa wood it can be painted with the brush to give you a really hard surface to work with further. Super glue is also a really good filler for narrow gaps. Rather than craft knives I use scalpels. Blades can be changed very easily and come in lots of shapes. Although I have fine drills, very often I use a small pointed scalpel blade to made small holes by simply rotating the blade.

STAGE 1

In the planning stage I looked at a bunch of shotguns online for reference and to get a feel for the variety of design and the detail in the engineering. What I end up with sometimes turns out a little different to how it started in my mind. Which is fine, it’s often just a bit of trail and error.

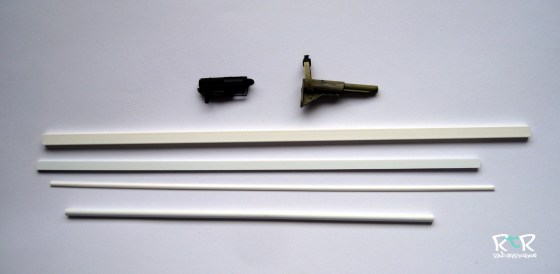

I did find a section of a rifle with trigger and guard in my bits box and a shoulder stock (which I ended up not using!). Got together the ‘strip styrene’ (it is called this by the firm that make it, ‘Evergreen Scale Models) which I thought I might use. I also used some sheet styrene not shown.

STAGE 2

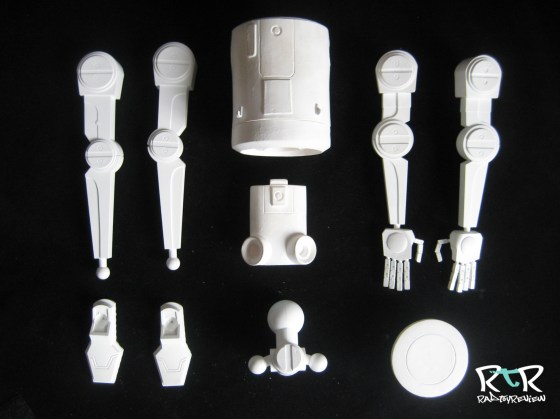

Some in progress pieces are shown below.

The two barrels were made from 5mm styrene tube. They were glued together and thin strip of 3mm semi circular styrene, turned over and glued along the top. As shotguns often break to load, I cut off a 4 mm section of the barrels to make the housing for the firing pin mechanism. The two short tubes making this section were then filled with 3mm styrene rod.

The part of the rifle from the bits box, that included trigger and guard, was cut to receive the first part of the barrels as a first fit. I did not set out to make an engineered masterpiece and therefore it will not actually hinge, but as you can see in the next picture, further shaping of this section and the front stock has shown where the barrel could pivot.

The back stock is 10mm by 6mm rectangular hollow section styrene to which I have glued small pieces of sheet styrene to block it in. An alternative stock could easily have been made of balsa wood.

The front stock is two pieces of 6mm by 2.5mm rectangular solid section styrene glue together and cut into the stock shape. Along the bottom edge a strip of 3mm semi circular styrene was glued. I added a front sight and strikers, using 1mm sheet, cut and shaped with scissors. Further sanding down and filling was done to complete the model and scratches were added to the front and back stock to give the impression of wear and tear.

STAGE 3

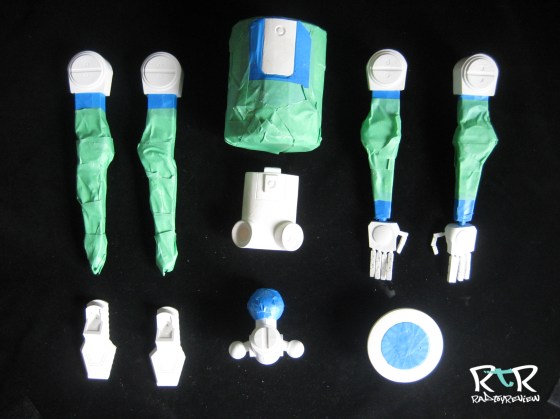

The shotgun was then washed in detergent to remove any grease marks and then sprayed with matt black acrylic paint. I have never seen the need to buy an air brush and always use Humbrol acrylic aerosol paints to a give a base colour.

I tend to use Games Workshop acrylic paints which are very good and are easy to get hold of, either at a local store or online. They come in a range of both basic and very useful blended colours. They are kind to brushes as there is no need to use solvents for cleaning. The names of the paints, I might as well use them, are referred to below.

The next stage was to paint the stocks. I did this by dry brushing, a technique that would hopefully leave the wear and tear scratches darker. Dry brushing is a technique of wetting a brush with paint and then almost drying it with paper towel, then wiping it across the area you are working on. Keep going until you get the effect you need.

Firstly, I used Games Workshop Scorched Brown, then GW Dark Flesh, then GW Desert Yellow and finally GW Desert Yellow mixed with a little bit of GW Skull White. The metal parts are dry brushed with GW Boltgun Metal. Where surfaces might be more worn than others, more drybrushing can be applied.

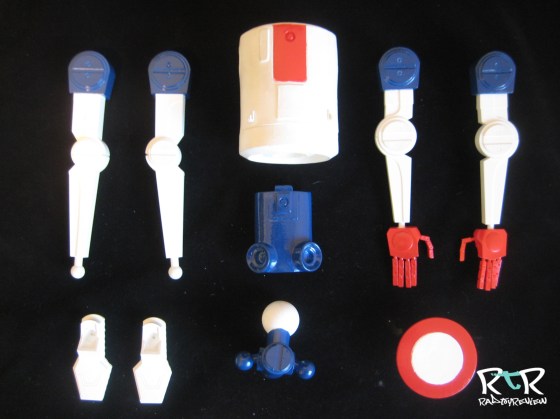

A tether added for good measure and you’re good to go!