Happy Valentine’s Day everyone! If you’re lonely and sad today.. take heart! A new Workshop awaits!

What a treat today is… A little back history first. When I first got into collecting 3A, I remember seeing all these pictures of Tommy Mission figures holding these awesome little baseball bats. They all had different decals, witty scribe.. some had blood splatters, nicks/scratches etc. I ordered my first Tommy fully expecting to have some variant packed in with him. To my surprise, no bat.. just a dumb glowing hand (kidding?). After a smidge of digging I came to learn that these amazing little things were handmade by a fellah who, going completely off his various forum names, seems to have an intense, yet healthy fascination with goats.

Huge thank you to Simon/Goatbot/Goatballs/Goaty for this fantastic workshop! He was kind enough to create not just one, but TWO different tutorials for us! The second we plan to post later in the week. This one is the most complex yet and you get play to play with power tools. Please be safe and don’t poke your eye out kid!

– Knives

Howdy folks, must be a slow news week as Knives has very kindly asked me to provide him with a tutorial or two… you lucky people .. its a big honor to have been asked so thanks mush.

To the bat tutorial then..

For those of you who feel the need for some blunt force trauma in your lives, nothing says emo better than 3 foot of hickory planted firmly in the jacobs… hopefully this tutorial will make enough sense so ye can make your very own baseball bat…

This is a wee bit more demanding and requires you have a few tools laying about but if you can do it, anything goes.

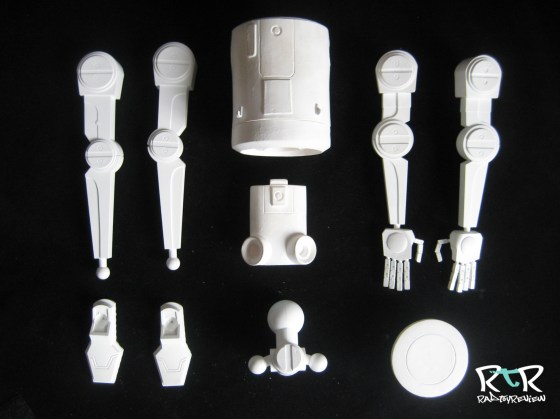

Materials :

- power drill, cordless preferred unless ye have a bench vice or indeed a wood lathe (I use an 18v hitachi cordless impact driver drill)

- fine toothed saw ( gents, mitre etc )

- wood rasp

- small hobby files or a dremel

- sandpaper or better still aluminium oxide cloth 80 , 120, 240 grit should do it

- 12 mm HARDWOOD doweling , available in most hardware stores and model hobby shops. Ye can use lengths of twig, sticks etc but this will make th job way harder..

- electrical tape, medical tape etc ( for the grip )

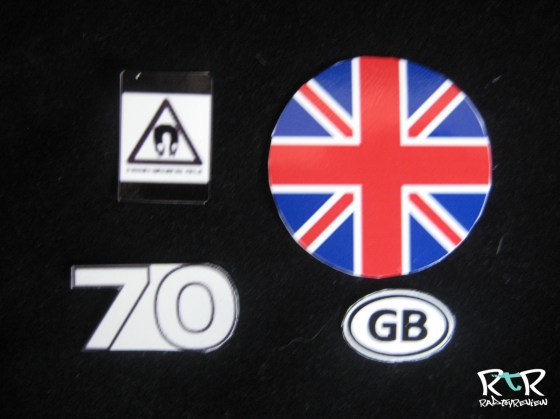

- paint, pens, decals

- bees wax or spray varnish

- COMMON SENSE

- dust mask

- Well ventilated work space

Okay this my method only ! Those of ye with better tools and workspaces will no doubt adapt accordingly, I apologize for the picture quality as it was cold and no one was willing to take pics of me making toy bats… bastards..

Also a shout out to dedguy for inspiration and for making bats look so frick’n cool

To start off with I find it best to sit on a wee box or something low to the floor with materials and tools close to hand. Then I measure and cut how many bats I want to make..the bat should be around 13.5 – 14 cms but the over all length ye want to work with should be about 17 cm.. The remainder should be enough to fit snugly into the chuck of the drill . Bats come in all shapes and sizes so decide on the look ye want before hand. I make bats of differing styles and also of differing handle widths to accommodate various hand sculpts. Note its better to go too thin as ye can always bulk out the handle with “grip tape”. After inserting the wood into the chuck, engage the power to see how well the woods been seated… if its off it will wobble alarmingly.. just re-house it until it spins ” true” .

I then put the drill on the floor and brace it with a well planted foot across the battery housing ( as per the picture above) when its stable, select th speed ye require ( higher speeds work best) and away ye go .

With one hand operating th drill trigger I use the wood rasp to waste away the rough shape of the bat. I work on the opposite side of the wood to where I’m positioned taking care not to impose too much pressure on the wood..

Working your way from the chuck to the end of teh bat will have the best results but be wary of lingering too long in one spot lest ye thin it out too much.

I work my way up from the chuck end along th barrel of the bat a couple of times then stop to see how I’m doing… if I’m satisfied I’ll take a sheet of abrasive paper 80 – 120 grit, fire up the drill again and use th paper to smooth and shape teh bat to the required shape and finish.

BE CAREFUL HERE .. you can grip th bat with the paper but be aware that it can snap if your grips too tight, also the transferred heat can cause nasty friction burns to you if yer not careful… try explaining that to your girl friend or nearest medical professional.

I usually leave the grip end until last as this reduces th likelihood of it snapping at the weakest point. I use a wee elliptical metal file to flare out the bottom of the handle and to create the hand stop at the end taking care to thin out the wood below the knob so as to make cutting off the wood sprue neater and easier.

Once yer satisfied ye can take the bat out, cut it off at the base and sand the base and top of the bat by hand .. If I’ve done this properly ye should now be teh proud owner of a 1/6 scale baseball bat !

or have a fine toothpick…

or maybe a burnt hand full of splinters.

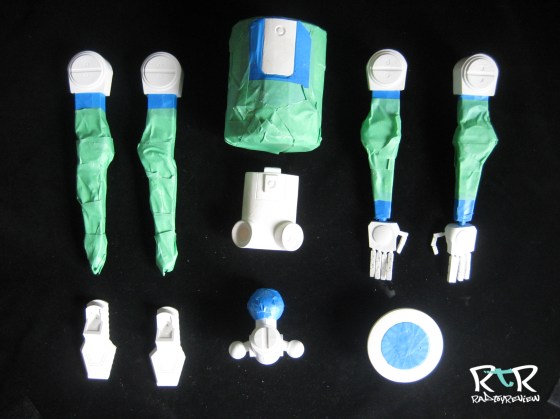

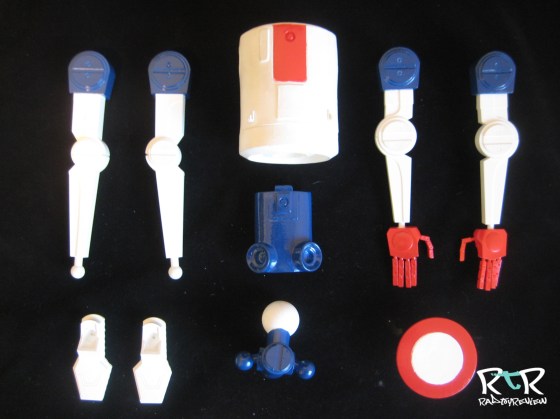

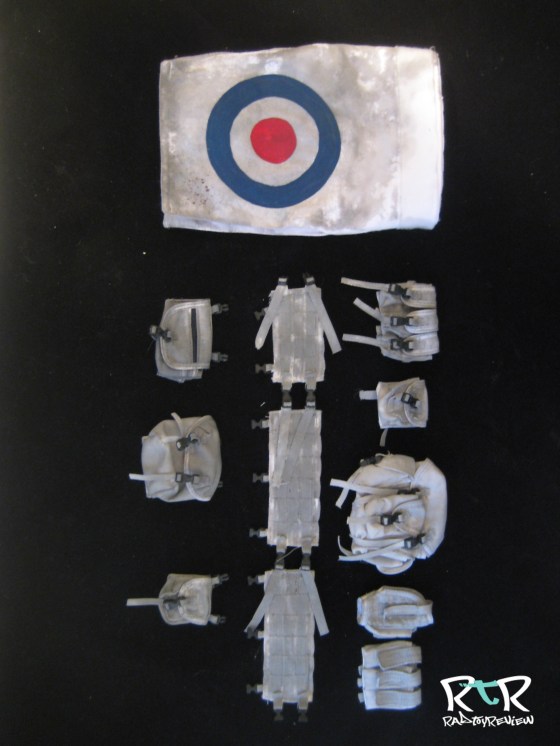

Once yer done with this part its then up to you on finishing touches. I usually polish the wood with beeswax, paint it if required, then add weathering and teh odd nick or scratch before a final coat of varnish .

Your AK crew is now tooled up and ready to roam the streets..or your shelves, doling out righteous woody justice !

Thats it …done and dusted.

Many thanks for your time and patience and a huge props to Rad Toy Review.

cheers !

We hope you enjoyed this Workshop. Check back later in the week as we bring you another from the mighty Goat!

We’d love to hear from you here, on our Facebook or Twitter page. We’d love for you to share with us your own customs. Let us know how we’re doing and what kind of workshops you’d like to see.